AI and IoT on Online Marine Management: The case of smart routing

| Artemios-Anargyros Semenoglou | Evangelos Spiliotis | Vassilios Assimakopoulos |

| Ioanna Makarouni | VHaris Doukas |

| National Technical University of Athens School of Electrical and Computer Engineering |

Abstract

Nowadays, the absolute majority of goods is transported by ship. Yet, the demand for maritime transport is continuously increasing, introducing both opportunities and risks for the shipping companies related to their business competition and operational planning. Simultaneously, data availability, algorithmic advances and computer power are exponentially growing, enabling significant improvements through the utilization of cutting-edge management systems. Undoubtedly, maritime industry is strongly affected by such developments as IoT and AI solutions facilitate real-time data collection and efficient calculations, introducing lots of potential for numerous optimization applications that can reduce cost, improve service and increase capacity. This article focuses on the case of smart routing. It is shown that exploitation of online data and advanced AI algorithms can reduce fuel cost, lessen traveling time and enhance safety, signifyingsome ways forward.

1. Introduction

|

The term maritime transport is used to describe the transport of people and goods by water. Nowadays, 80% of the goods in terms of volume and 70% in terms of value are transported by ship. Even more interesting is the increasing demand for maritime transport according to the United Nations Conference on Trade And Development (UNCTAD) review of maritime transport [1-2]. In 2016, seaborne trade volumes (10.3 billion tons) increased by 2.6%, which was more than the increase by 1.8% in 2015. In 2017, the volumes expanded by another 4%, while for 2018 UNCTAD projects another increase of about 4%. According to long term forecasts, an average annual increase of 3.8% is expected up to 2023. All the above paint the picture of maritime transport becoming increasingly more important and competitive, meaning that research and developments related to its applications are bound to bring even more benefits. A strong ally towards this direction, is Artificial Intelligence (AI) and Internet of Things (IoT) technologies which enable real-time data collection from multiple and, in most cases, trustworthy sources, as well as their efficient storage, processing and analysis. |

When it comes to maritime industry, ship monitoring through on-site sensors is continuously becoming cheaper and more accurate, enabling shipping companies to collect data from their ships and exploit them for better management and planning [3]. This is exactly where real profits lie: With IoT comes a huge amount of data, from which valuable insights can be gleaned. Monitoring the efficiency of a ship is simply not enough for surviving in such a competitive environment and important decisions must be made regarding how such information will transform day-to-day operations at sea. AI algorithms facilitate the processing of large unstructured datasets, enabling at the same time computations in an unsupervised and self-learning way. As such, shipping companies can automatically extract valuable information from the collected data and exploit it to support decisions, optimize operations, reduce cost inefficiencies and improve services. Exploiting relevant online solutions will determine how the maritime landscape will look like in the following years. |

2. Smart routing towards profit maximization

|

Smart routing is a special application where IoT and AI technologies are going to contribute in better management and planning. According to S.A. Lawrence [4], routing and scheduling problems can be divided into industrial, tramp and liner shipping ones. Liner shipping is comparable to a bus line. Ships operate on their assigned route based on a published schedule and a fixed port rotation. On the other hand, tramp shipping can be compared to a taxi service. Vessels have no fixed route, schedule or itinerary. Finally, in industrial shipping the ships are controlled by the owner of the cargo and are scheduled so that the needs of the organization as part of the supply chain are covered. In this regard, depending on the examined problem, defining the optimal route for maximizing profit may greatly differ both in terms of criteria, options and limitations [5-6-7]. Yet, in all cases, minimizing fuel consumption is a prerequisite for mitigating cost inefficiencies. The importance of applying smart routing can be easily proved if we analyze the impact of traveling distance (direction and turns) and speed to the operating cost. Given that ships travel relatively slow, their trips are longer and more risky in terms of delays and extreme weather conditions, influencing their total operating cost which consists of different types of expenses. |

Fuel cost are the most important one and represents as much as 50-60% of the total [12]. A common practice for keeping it low is to deliberately slow down the speed of the ship (slow steaming), increasing however that way the cost of personnel, insurance and inventory. A secondary cost, which has become important in the recent years, is the environmental footprint of the vessel. According to the GHG study in 2014 [8], the overall CO2 emissions from the international maritime shipping comprise approximately 2.2% of the global CO2 emissions, forcing the authorities to penalize environmental unfriendly ships. Harbor fees and penalties for missing the proper time windows, as well as security related issues (e.g. extreme weather conditions and piracy) should also be taken into account. Many studies [9-10-11] show that it is possible through smart routing to reduce the fuel consumption up to 20-25% when compared to sailing with an average speed. Such practices would also allow more space in the ship to be allocated to cargo generating revenue, further increasing the potential profit of each trip, while also avoiding risks. |

3. An innovative system for online management of routes

|

This article demonstrates the potential benefits of smart routing in maritime industry by presenting a relevant AI and IoT based system for shipping management. For reasons of simplicity, the system deals with liner shipping problems, optimizing the speed and direction of a given ship in order to reduce its fuel cost and minimize the risk of delay. Accordingly, the system can be expanded for considering more of the operating expenses discussed earlier.

3.1 System set up

The aim of the proposed system is to define the optimal route for arriving at a specific destination from a given starting point by reducing the fuel usage. These points could potentially be the vessel’s ports of origin and destination or certain coordinates in the middle. The optimization algorithm considers numerous factors, such as the expected time of arrival (ETA) and the operational constraints of the engine of the vessel (minimum and maximum sailing speed, speed-fuel consumption curves, etc.). In order for the routing to be reliable in each trip, exogenous variables are also part of the model. This includes natural and weather conditions that adjust the vessel’s nominal speed. Thus, the optimal route is computed, while respecting certain limitations are set by the user. Arriving to the destination within the expected time frame to avoid additional harbor fees and operating the engine within the bounds set by the technical specifications are such limitation. The output of the system is a series of waypoints leading to the set destination and the proposed sailing speed for each part of the trip.

3.2 Space modeling

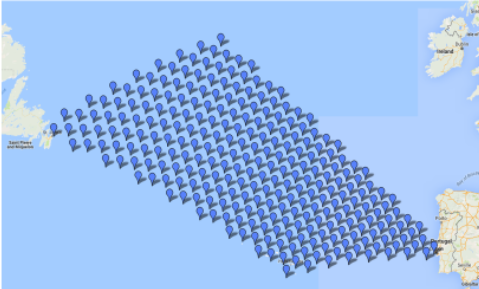

Given that the possible solutions when designing an optimal route are infinte, in terms of intermediate waypoints, it is critical to model the space between the point of origin (A) and the destination (B) in a discrete way, as presented in Figure 1. In this respect, the space is transformed into a grid of nodes and edges of reasonable distances between each other. More specifically, starting from point A and up to point B, the great-circle is drawn and then divided in a set number of smaller distances. From each such split point a vertical line is drawn, representing different levels of progression towards the destination, and potential waypoints for the vessel are placed on it. These waypoints are the nodes of the grid. The potential connections between the waypoints in a certain level and the waypoints in the next level represent the possible routes the vessel can take and these are the edges of the grid. The size of the grid is limited by the maximum distance the vessel could possibly cover while sailing with the maximum speed and still arriving in time in the destination

3.3 Route & speed optimization

The proposed route must minimize the cost of the trip and ensure that the vessel will arrive at the destination within the intended time window.

The main challenge is that, unlike most other routing problems, in which the cost of moving between a set of neighboring points remains the same,

the proposed algorithm considers weather conditions for calculating the actual speed of the vessel and the respective costs.

This results in different costs for the same distance in different points in time.

In this regard, as a first step, the algorithm expands all existing routes. Given that the vessels is in a specific waypoint at a specific time, the algorithm considers all the possible actions from there. This set of available actions consists of movements to different waypoints in the next level with different speeds, thus arriving in different times having paid different costs. In the second phase, the algorithm evaluates the existing solutions. If a solution that is leading the vessel is missing the desired time of arrival to the destination, then it is discarded. The same also happens for solutions which lead to the vessel being in the same waypoint later in time having spent more fuel compared to other alternatives. This allows the algorithm to keep an otherwise exponentially increasing number of existing solutions manageable. These steps are repeated starting from the first level, up until the level of the final destination. At that point, from the set of kept solutions the algorithm chooses the one having the minimum cost while respecting time limitations. Note that, based on its AI elements, the algorithm is continuously improved, learning from past mistakes and identifying best practices. In practice, the optimization process described above is achieved by combining three individual machine learning models into an integrated AI solution. The first one, responsible for identifying the best route, is based on the Breadth-First Search algorithm, in which the current level is processed prior to moving on to the nodes at the next depth level. The second one, based on a neural network, is utilized for empirically estimating the actual speed of the vessel according to its nominal speed and forecasted weather conditions. The last one, based on a decision tree, adjusts the speed-fuel consumption curve of the vessel (as provided by the manufacturer), so that it better represents reality and captures possible variations due to aging, deterioration, malfunctions, etc. |

Figure 1: The solution space of the model for a given route from point A (St. John's, Canada) to B (Lisbon, Portugal).

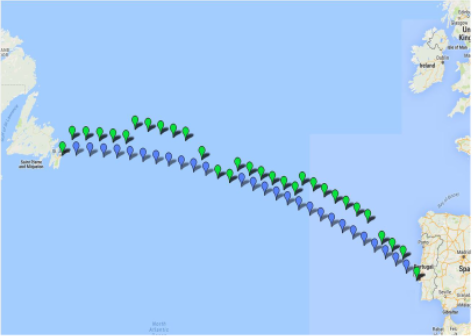

As a case study, a scheduled trip from Canada to Portugal was examinedand the route proposed by the system was compared to

typical strategies followed by many shipping companies. More specifically, two different scenarios wereconsidered,

according to which the vessel follows the minimum distance (great circle distance) between the two points and its speed is either constant or

adjusted (see Figure 2).

Figure 2: The proposed route (Green route) and the great circle distance (Blue route) from point A (St. John's, Canada) to B (Lisbon, Portugal).

|

4. Conclusions

|

The algorithm is implemented so that it is useful both for planning the trip of the ship and adjusting its route while on its way based on new information arriving (weather, natural conditions, etc.). This is essential given that a trip may last several weeks, making the initial plans less realistic and cost efficient. Assuming perfectly accurate data about the status of the vessel and the conditions in a specific area, the algorithm is able to optimize any given trip. Any deviation from the expected outcome (delays, need for adjusting the speed or the direction, etc.) is caused by inaccuracies in the input data leading to suboptimal routing. Thus, getting reliable input for the model becomes the main challenge in the effort of optimizing a route and that is exactly where IoT is essential, improve the reliability of the system in three ways: A) Regarding the input data, past systems were dependent on humans providing the necessary information. Operators had to manually import the data every time the model was recalculated and, therefore, the output was outdated and susceptible to human error. This also increased the effort on behalf of the operator reducing the utility of the tool. Nowadays, an increasing number of installed sensors results to more real-time and accurate data related to fuel consumption, engine performance, etc. The data arrive in shorter intervals, creating an immediate feedback loop and allowing for better route optimization with minimal human intervention. |

B) A significant portion of the data used for optimizing the route is forecasts about the conditions in a specific area in the future. As a result there is an inherent uncertainty in the information provided. At the same time, properly analyzed data from the past could potentially provide useful insights about the future, reducing the said uncertainty. Recent developments in the areas of machine learning and deep learning resulted in methods, which are able to identify and model hidden patterns in the data. The output of such methods could be used in conjunction with current forecasts to reduce the uncertainty of the future or at least provide an early warning. C) Before executing the optimization algorithm, a link should be defined between the exogenous variables and the effect they have on the speed, fuel consumption and cost. In the past this task required operators to model this effect and define the respective function. This approach inevitably introduces errors since it is very difficult to manually model these complex relations. Regarding this issue, machine learning methods have the ability to learn from past data and create complex models, which capture more accurately the effect the environment has on the operation of the ship. |

Overall, this solution can be proven a powerful tool for optimizing a vessel’s route and reducing the operating costs. By taking advantage of recent developments in the fields of AI and IoT, even better results can be achieved changing the future maritime transportation.

References

1. UNCTAD. (2017) Review of Maritime Transport, 2017. United Nations, New York and Geneva

2. UNCTAD. (2018) Review of Maritime Transport, 2018. United Nations, New York and Geneva

3. Zhang, S.-k., Shi, G.-y., Liu, Z.-j., Zhao, Z.-w. & Wu, Z.-l. (2018). Data-driven based automatic maritime routing from massive AIS trajectories in the face of disparity. Ocean Engineering, 155, 240-250.

4. Lawrence S.A. (1972) International Sea Transport: The Years Ahead, Lexington Books

5. Ronen, D. (2013) Cargo ships routing and scheduling: Survey of models and problems. European Journal of Operational Research, 12, Issue 2, 119-126.

6. Christiansen, M., Fagerholt, B., Ronen, D. (2004) Ship Routing and Scheduling: Status and Perspectives. Transportation Science, 38, 1-18.

7. Christiansen, M., Fagerholt, K., Nygreen, B., Ronen, D. (2013) Ship routing and scheduling in the new millennium. European Journal of Operational Research, 228, Issue 3, 467-483.

8. International Maritime Organization. (2015) Third IMO Greenhouse Gas Study 2014, Executive Summary

9. Kim, J.-G., Kim, H.-J., Jun, H.-B., Kim, C.-M. (2016) Optimizing Ship Speed to Minimize Total Fuel Consumption with Multiple Time Windows. Mathematical Problems in Engineering, 1-7.

10. Fagerholt, K., Laporte, G. &Norstad, I. (2010) Reducing fuel emissions by optimizing speed on shipping routes. Journal of the Operational Research Society, 61(3), 523-52

11. Prpic-Orsic, J., Vettor, R., Guedes Soares, C. &Faltinsen, O. (2015). Influence of ship routes on fuel consumption and CO2 emission. In book: Maritime Technology and Engineering, 857-864, Taylor & Francis Group.

12. World Shipping Council (2008) Record Fuel Prices Place Stress On Ocean Shipping. Available at http://www.worldshipping.org/pdf/WSC_fuel_statement_final.pdf